Our Mission

We are a leading clinical late-stage fully integrated biopharmaceutical stem cell company with over 15 years experience based in Heidelberg, Germany.

We focus on innovative stem cell therapies for patients suffering from severe inflammation-driven diseases with high unmet medical need and to provide a new and innovative standard of care for these patients, who currently have no satisfactory treatment options available.

Our ABCB5+ mesenchymal stromal cells as pure drug substance can make a real difference for the lives of these patients, e.g., in Epidermolysis Bullosa, having the potential to be a real game changer.

Targeting inflammation by our innovative proprietary cell therapy enables tissues the recovery of normal physiological function.

We fight rare diseases!

Indications

We are dedicated to developing innovative therapies for patients suffering from severe inflammation driven diseases, such as our lead indication Epidermolysis bullosa, based on our proprietary ABCB5+ mesenchymal stromal cells (MSCs) platform technology. Hereby we focus on rare and orphan diseases.

Epidermolysis Bullosa (EB)

With our lead indication EB -orphan & rare-, "the worst disease you have never heard of", we are in a pivotal phase 3 clinical trial in Europe and the US with EBESANAR®.

With our unique product characteristics and mode of action and the systemic (intra-venous) approach our cells are first in class and best in class by targeting external and internal wounds, leading to a reduction of overall disease burden in patients by significant reduction of wounds, enabling recovery of normal physiological function of the affected tissue and preventing the formation of new wounds.

Chronic venous ulcers (CVU)

Our innovative proprietary cell therapy with ABCB5+ mesenchymal stromal cells for the treatment of non-healing chronic venous wounds has already been granted with a national market approval for external use in CVU patients, by the Paul-Ehrlich-Institute in Germany in 2021 (AMESANAR®).

The cell therapy targets inflammation and is enabling recovery of normal physiological function and initiating neo-vascularization after topical application. Further research and clinical trials for treating patients with diabetic foot ulcers are ongoing.

Late-stage clinical development

We develop clinical research programs hand in hand with world-leading experts, focusing on patients with unmet medical needs, e.g., in rare pediatric and dermatological diseases accompanied by and/or based on systemic inflammation.

Based on the mode of action and relevant potency assays, RHEACELL has a significant pipeline to further broaden its clinical development and market access into other rare and orphan diseases.

We conduct several national and international multicenter late-stage clinical trials.

Technology

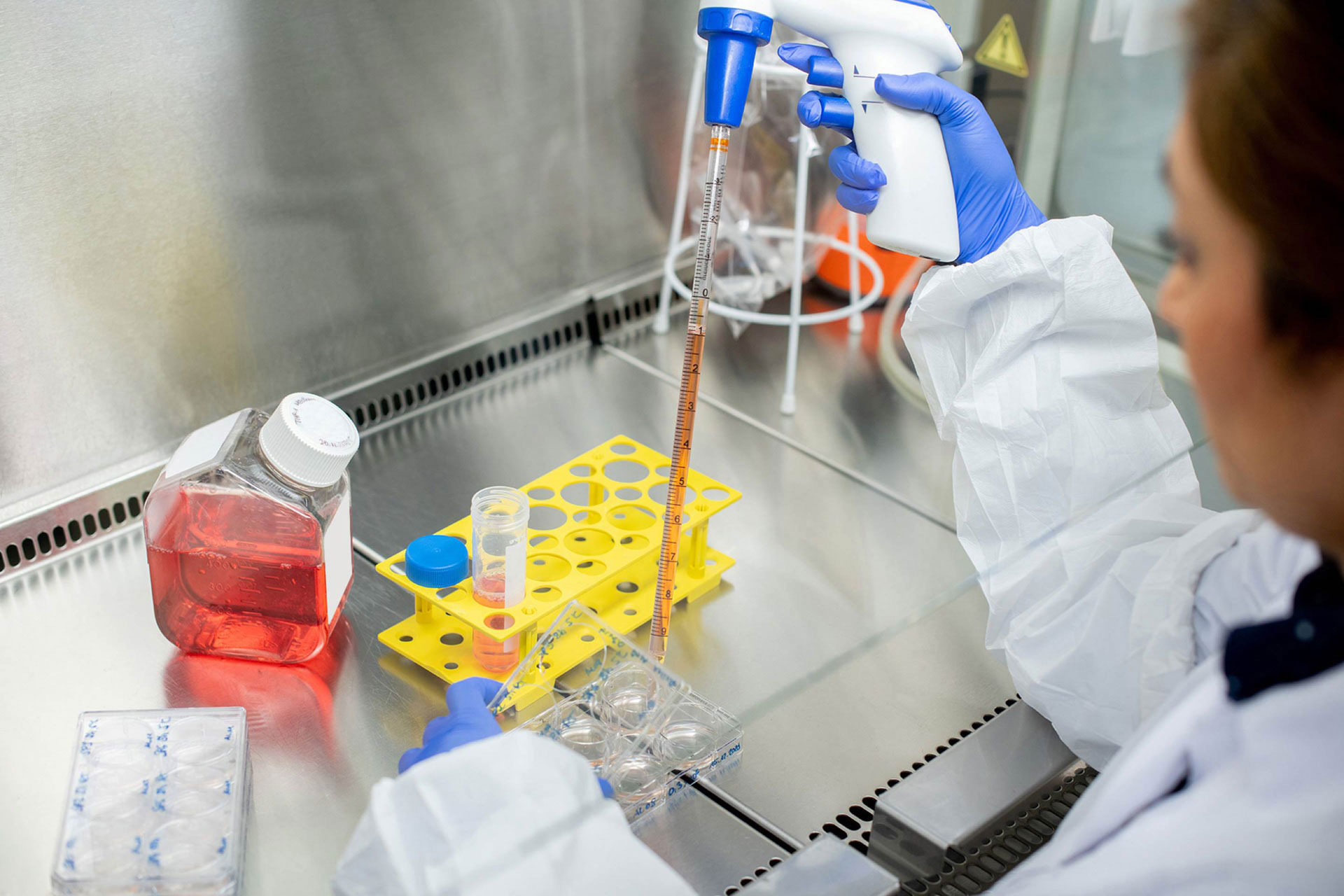

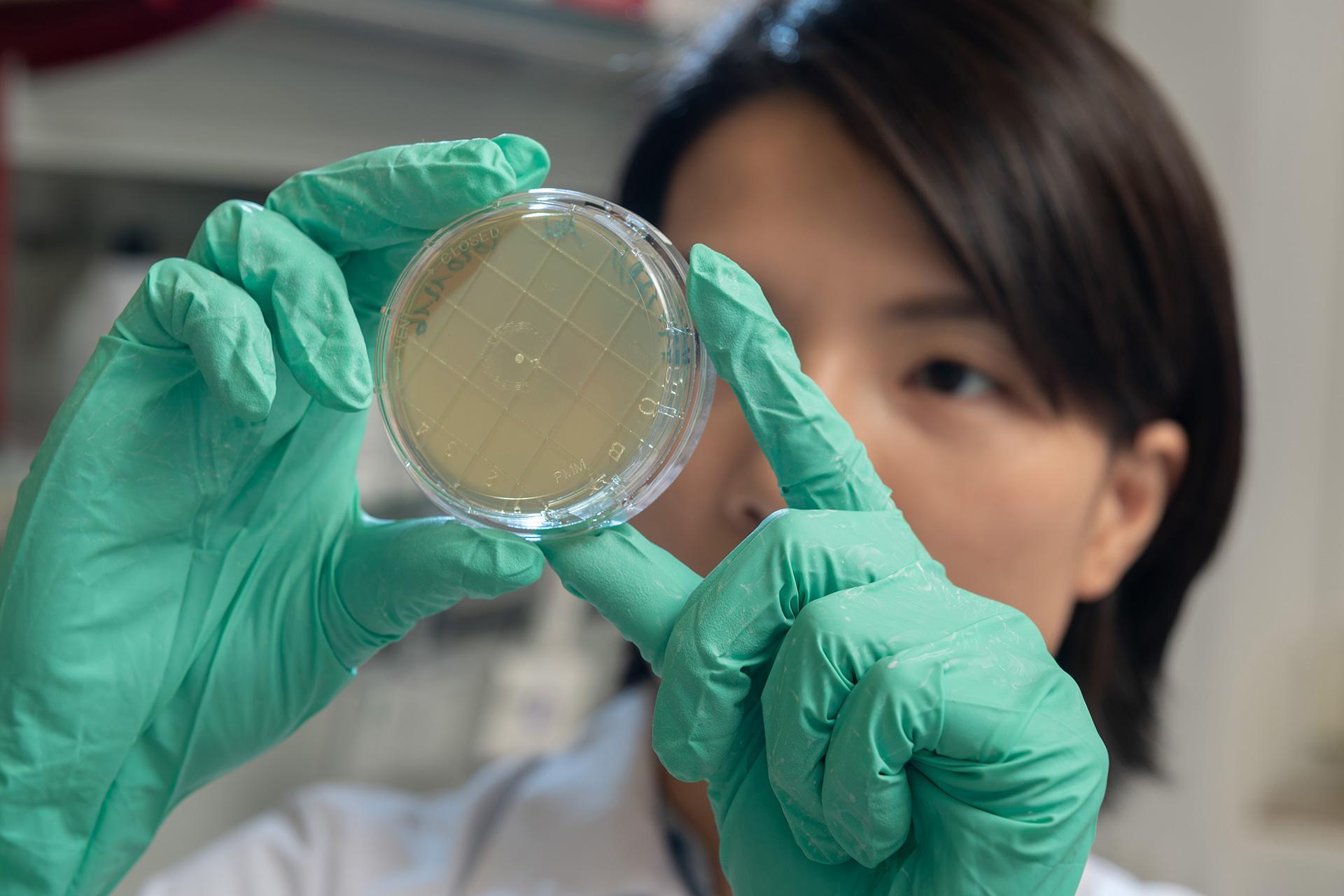

Our innovative proprietary cell therapy is a pure drug substance consisting of ABCB5+ mesenchymal stromal cells.

Produced in our all-in-house GMP facility, from production to batch release, based on validated potency assays, we have full control of all crucial steps to guarantee best pharmaceutical quality.

With our off-the-shelf manufacturing process serving global market needs, we have a validated, GMP-certified, and scalable allogenic high through-put manufacturing processes.

We hold the full manufacturing licenses for AMESANAR® (CVU) and for EBESANAR® (Epidermolysis Bullosa).

We hold world-wide IP protection by a comprehensive patent portfolio on ABCB5, exclusively licensed by RHEACELL from Boston Children's Hospital and Brigham and Womens Hospital, Harvard Medical School, Boston, several of these co-owned by RHEACELL, and the proprietary in -house know-how gives us a competitive advantage in the industry.

Our history

RMAT designation (FDA) for EBESANAR®

Merger TICEBA and RHEACELL

Manufacturing license granted (AMG) for EBESANAR®

National marketing authorization in Germany granted for AMESANAR®

Pediatric Investigation Plan (PIP) approved by PDCO (EMA) for RHEACELL

National marketing authorization applied for in Germany

Technology platform patent granted ("H.F.M Stem Cells")

First clinical trial using ABCB5+ cells

Manufacturing license granted (AMG – German Medicinal Products Act) für AMESANAR®

Creation of RHEACELL

Approval granted for tissue procurement and processing

TICEBA launches business activities

First description of ABCB5+ cells and creation of TICEBA

First ABCB5 patent